FDT projects

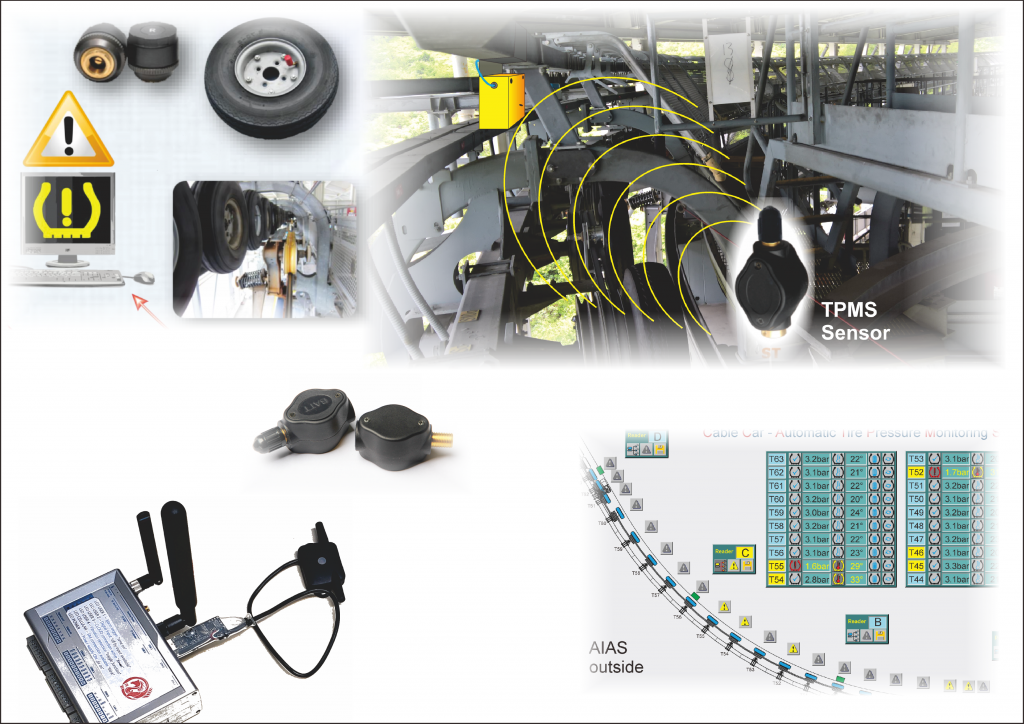

IoT-ATPMS

The IoT Automatic Tire Pressure Monitoring System (IoT-ATPMS), which can measure and monitor the pressure and temperature of an arbitrary number of conveyor tires in different installation as for example on automatic grip cable car stations, amusement rides and industrial plants.

It is a full-scale production solution with only industrial grade components used to provide a highest reliability.

The equipment is designed according to the required environmental conditions and meets all relevant applicable standards.

Local and/or remote monitoring is available with adaptable SCADA visualization and automatic alarm system.

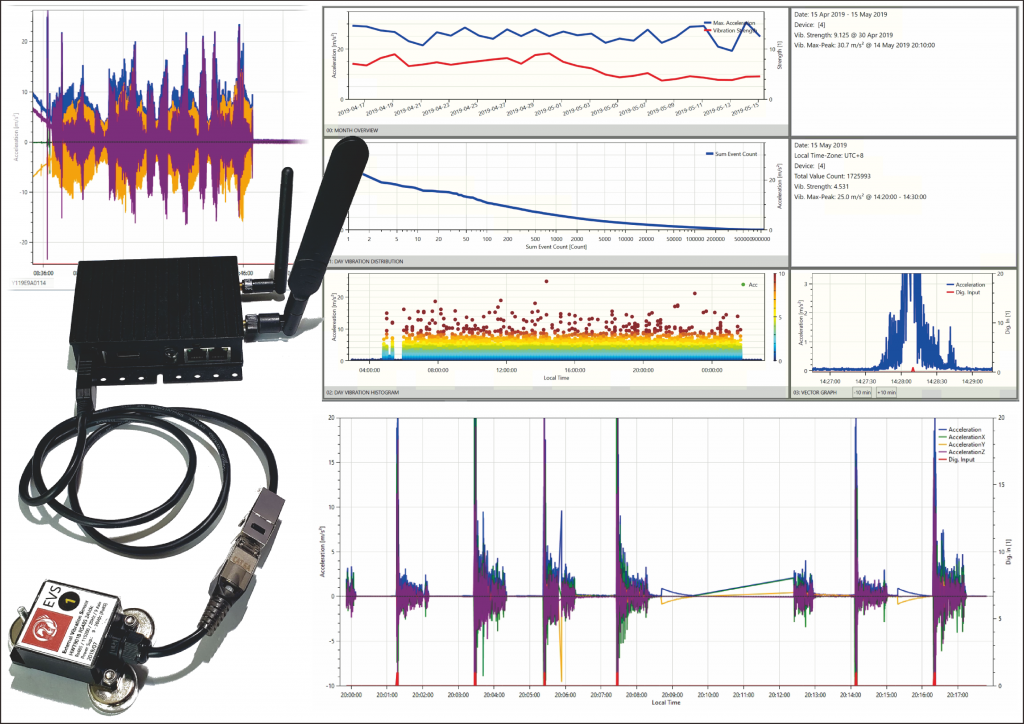

IoT-VMS

The IoT Vibration Monitoring System (IoT-VMS) is able to measure and monitor using high numbers of sensors a high-quality vibration data or other sensor solutions (temperature, liquid flow, power, etc.).

The IoT solution allows the collection of data from various sensors in different networks and positions, no matter if the data transmission will be over SIM-Modem, Wi-Fi, optical fibre or other.

A Data Collector Server is reading and processing the incoming data packages which it collects from all connected IoT gateways, to evaluate the received data frames and to pre-process the data.

A Realtime data analysis module continuously life-checks (watchdog) the IoT modules. It monitors the regular reception of data from the IoT units with an alarm function and tabular presentation of the units in operation.

A simple SCADA is provided for visualization of the software function and activity.

WAPDT

The Wireless Safety Power & Data Transmission (WAPDT) system, is a project that allows the remote control of a safety contact, by means of a coil coupling, in order to switch between power supply and which safety data is transferred to control the operating system.

It is designed for special applications in the industrial field of automation and autonomous handling of fleets, as well as for controlling the status of cabin doors for cableways, amusement rides and alike.

A similar project using RFID transponders, which is already in operation, is now being revised to gain higher system availability.

Various applications and transmission variations are being worked on.

SCADA OPC-UA

A SCADA solution that is implemented in parallel to the Main Plant SCADA and allows a total autonomous visualization of parameters for the customer without any interference to the operational system.

This will be enabled by obtaining all the plant data through an additional OPC-UA Server with its own database, and which can be accessed from the separate independent SCADA.

It further has the advantage of the independent SCADA being fully free for additional implementations/developments with possible access and display from the WEB (with secure access) and also on smartphones/tablets (for easier and faster control and adjustments in station and remote surveillance & information control).

Call to Action

We are looking forward to hearing from you soon and please do not hesitate to ask for more detailed information of your desired subject.